ANALOGUE

With a vast array of technologies and our 40+ years in the specialist cable market, we produce cables to suit every budget to maximise the potential of your beloved system. With a vast array of technologies and our 40+ years in the specialist cable market, we produce cables to suit every budget to maximise the potential of your beloved system.

DIGITAL

Whether you’re connecting your TV to a sound bar or music server to a DAC, QED has a digital cable to meet your requirements. Our cables are tried and tested to ensure you get the best performance from your digital sources.

PHONO TO PHONO

When connecting your analogue sources such as your CD player or turntable to your amplifier, here at QED, we have a cable to suit your system. From our entry level Profile cable through to our flagship Signature Interconnect.

XLR

Using our unique Tri-Conductor technology and Neutrik XX-14 balanced plugs, our XLR cables offer the cleanest possible sound from a specialist XLR cable, whilst also incorporating our Ferrite insulation to eliminate timing errors.

DIGITAL COAXIAL

An alternative to optical, our premium digital coaxial cables use a specially designed cable cordage and unique plug design to achieve the precise signal characteristics required for high resolution and multi-channel audio.

USB A-B

With our high end USB A-B we isolate the power and data conductors preventing any potential cross talk, therefore meaning less jitter and an enhanced audio performance.

USB A-B MICRO

For use with Laptops/Computers and portable headphone amps/dacs, the QED reference USB A-Micro B uses our Ferrite insulation to reduce Jitter, as well as isolating the data and power lanes for a cleaner overall signal.

USB A-MINI B

Triple magnet screening and 24K gold plugs makes our Performance USB A-Mini B the best in its class.

JACK TO PHONO

Connecting your mobile device/tablet to your audio system has never been easier with our 2 step 3.5mm jack for a simpler connection.

HDMI

Using our in house HDMI testing facility, QED have designed premium HDMI cables to suit any budget. From our flexible and slimline profile to our exceptional Reference HDMI with its BandPass filter technology to reduce Jitter to Ultra low levels

OPTICAL

For all of your Optical needs, QED has an optical cable for you. For the more advanced, high bandwidth signals, Reference Optical Quartz uses glass technology to accurately send the information from source to receiver.

ETHERNET

The most common type of cable used for connecting products on a wired network. This cable connects wired devices together to the local network for file sharing and Internet access.

SUBWOOFER CABLE

Using technologies from our analogue cables such as complimentary conductor technology, your subwoofer will always perform to its best capability.

What makes our 'Audio 40' analogue interconnects so special?

QED are proud to present an entirely new range of analog audio interconnect cables to celebrate 40 years at the forefront of British Designed audio cables.

There are three cables in the range representing the long established Performance, Reference and Signature designations which have always corresponded to the "good better best" principle of product hierarchy. However the whole range has been developed using a strict top down approach which means that all three cables share an almost identical construction and geometry with the Signature cable representing the ideal cost no object original state of the design and the Performance cable its cost engineered alternative. The Reference cable represents the perfect balance of performance against the law of diminishing returns omitting only the most expensive components.

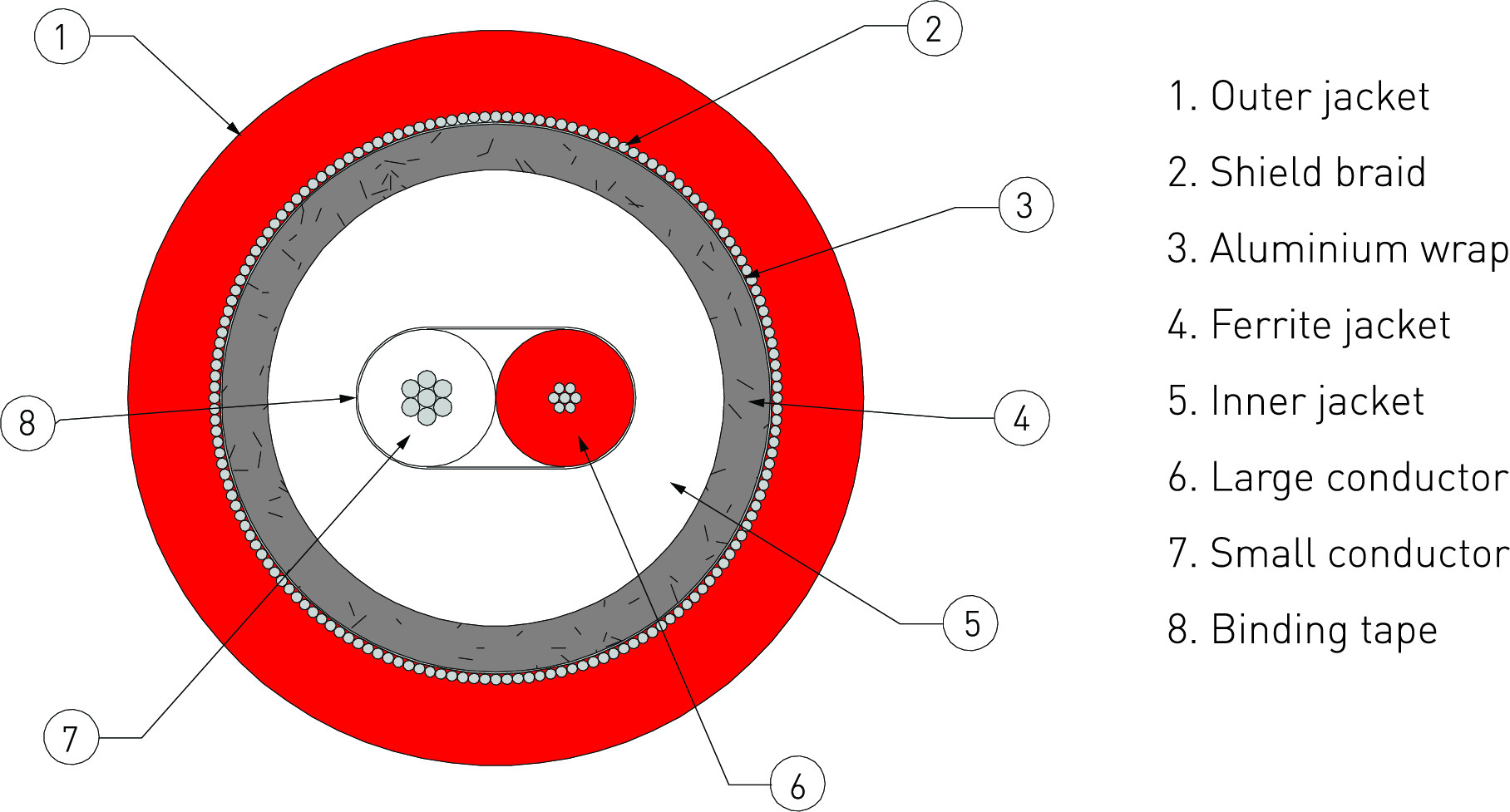

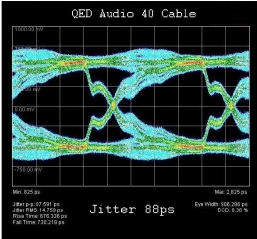

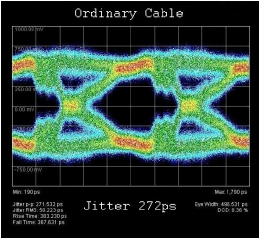

The cordage is designed primarily for low capacitance as this has been identified by QED as one factor which leads to a hi-fidelity experience and makes for a tight sound which retains the rhythm of the original piece. Further unique steps have also been taken to eliminate minute timing errors in the cable. Our new Complementary Conductor(TM) geometry is used throughout the range and utilises two conductors of different diameters to carry the same audio signal. This is thought to have the effect of providing an alternative path for high frequency audio components which might otherwise become time smeared in a single audio pathway. Another innovation added to the entire range is the specially impregnated PVC jacket containing 10% Zn/Mn ferrite material. This absorbs very high frequency noise signals and audio signal components which are thought to have an adverse affect on the micro-timing of the audio signal. Low constant dielectric materials such as foamed polyethylene or teflon have been used throughout the range to cut down on the amount of audio signal energy lost due to cable capacitance and all of these measures have been applied under the consultation of leading industry experts. We have been able to measure the affects of these improvements using our high frequency cable test suite. The two diagrams show the difference measured in a high frequency data stream applied to a cable without the improvements (left) and with the improvements (right). The ability to accurately transmit high frequency impulses means that within the audio band timing and dynamics should be improved.

Additionally the new locking plug does nothing to spoil the low jitter, low noise signal provided by the cordage. The new low eddy current design features small high purity copper conductors in place of the usual large volume brass body found in ordinary high quality plugs. This cuts down or eliminates the tendency for the changing magnetic field in the conductor to induce eddy currents which can affect the micro-timing of the audio signal. Coupled with its hollow central pin, which is designed to combat the skin effect in background image the same way as our X-Tube speaker cables, the new QED Analoc plug maintains the fidelity of the audio signal from start to finish.

Traditionally high quality RCA phono plugs (designed

in the 1940s and still used today for domestic

unbalanced audio connections) have been machined

from solid brass. Brass is a reasonably inexpensive

material and can be easily worked so it lends itself to

use in bespoke designs which attempt to improve

upon more basic implementations of the original RCA

plug. Unfortunately there are a few problems with

the use of bulk brass, the first being its low

conductivity compared to pure copper. Pure copper

plugs would be prohibitively expensive and so are

not used but if the high purity copper conductors were confined to just the pin section and the small contact areas required for the return

ring then this would be economically viable.

Traditionally high quality RCA phono plugs (designed

in the 1940s and still used today for domestic

unbalanced audio connections) have been machined

from solid brass. Brass is a reasonably inexpensive

material and can be easily worked so it lends itself to

use in bespoke designs which attempt to improve

upon more basic implementations of the original RCA

plug. Unfortunately there are a few problems with

the use of bulk brass, the first being its low

conductivity compared to pure copper. Pure copper

plugs would be prohibitively expensive and so are

not used but if the high purity copper conductors were confined to just the pin section and the small contact areas required for the return

ring then this would be economically viable.

QED's new Analoc plugs take advantage of this idea

and provide a high purity copper connection without

the use of bulky brass plug bodies. The pin section is

made from a hollow tube of high purity copper and

the ground return is reduced to just two of the

normal six leaves. This has the dual effect of

providing a low resistance path for the tiny signal

currents flowing in line level unbalanced connections

and cuts out the possibility of eddy currents forming

in the large volume of the plug body which would

otherwise form part of the return path for the signal.

Eddy currents are swirling circular currents which build up in any conductor where there is a variable magnetic field acting on it such as

when an ac signal is applied. Eddy currents flowing in a conductor of a given resistivity

necessarily dissipate energy and this energy loss is proportional to the square of the

diameter of the conductor - so the smaller this can be kept, the less the effect of eddy

currents on the delicate audio signal. Add to this the fact that eddy currents can persist

for a short time after the field is removed and always create a field that opposes that

which creates them it can be seen that eliminating this phenomenon can lead to

improved transmission of the audio signal - especially in the area of minute timing

effects.

QED's new Analoc plugs take advantage of this idea

and provide a high purity copper connection without

the use of bulky brass plug bodies. The pin section is

made from a hollow tube of high purity copper and

the ground return is reduced to just two of the

normal six leaves. This has the dual effect of

providing a low resistance path for the tiny signal

currents flowing in line level unbalanced connections

and cuts out the possibility of eddy currents forming

in the large volume of the plug body which would

otherwise form part of the return path for the signal.

Eddy currents are swirling circular currents which build up in any conductor where there is a variable magnetic field acting on it such as

when an ac signal is applied. Eddy currents flowing in a conductor of a given resistivity

necessarily dissipate energy and this energy loss is proportional to the square of the

diameter of the conductor - so the smaller this can be kept, the less the effect of eddy

currents on the delicate audio signal. Add to this the fact that eddy currents can persist

for a short time after the field is removed and always create a field that opposes that

which creates them it can be seen that eliminating this phenomenon can lead to

improved transmission of the audio signal - especially in the area of minute timing

effects.

Eddy currents also give rise to the skin effect wherein current increasingly flows towards the outside of the conductor as frequency increases. By removing the central portion of the copper pin section we have reduced eddy currents here also and thus combated the skin effect and reduced self inductance in a similar way to that employed in our X-tube speaker cables.

Because the contact area of the outer ground ring has been reduced it is necessary to provide a very firm connection indeed and so all Analoc plugs have a locking feature built in so that as the barrel is screwed up tight, the clamping force is increased making for a super noise free and secure connection for life.

The high purity copper conductors featured in the Analoc range come with gold plating at Reference level and rhodium plating for the Signature plugs. This plating is there to maintain low contact resistance throughout the life of the product due to the stability and low reactivity of these metals. Although copper is the second best electrical conductor (behind silver) it does react with oxygen and can tarnish over time increasing the contact resistance and therefore increasing distortion of the original signal. Rhodium has the advantage for use as a plating material due to its superior hardness.

QED Analoc comes as standard on the Audio 40 interconnect range and can be purchased separately to be included in custom cable projects.