ANALOGUE

With a vast array of technologies and our 40+ years in the specialist cable market, we produce cables to suit every budget to maximise the potential of your beloved system. With a vast array of technologies and our 40+ years in the specialist cable market, we produce cables to suit every budget to maximise the potential of your beloved system.

DIGITAL

Whether you’re connecting your TV to a sound bar or music server to a DAC, QED has a digital cable to meet your requirements. Our cables are tried and tested to ensure you get the best performance from your digital sources.

PHONO TO PHONO

When connecting your analogue sources such as your CD player or turntable to your amplifier, here at QED, we have a cable to suit your system. From our entry level Profile cable through to our flagship Signature Interconnect.

XLR

Using our unique Tri-Conductor technology and Neutrik XX-14 balanced plugs, our XLR cables offer the cleanest possible sound from a specialist XLR cable, whilst also incorporating our Ferrite insulation to eliminate timing errors.

DIGITAL COAXIAL

An alternative to optical, our premium digital coaxial cables use a specially designed cable cordage and unique plug design to achieve the precise signal characteristics required for high resolution and multi-channel audio.

USB A-B

With our high end USB A-B we isolate the power and data conductors preventing any potential cross talk, therefore meaning less jitter and an enhanced audio performance.

USB A-B MICRO

For use with Laptops/Computers and portable headphone amps/dacs, the QED reference USB A-Micro B uses our Ferrite insulation to reduce Jitter, as well as isolating the data and power lanes for a cleaner overall signal.

USB A-MINI B

Triple magnet screening and 24K gold plugs makes our Performance USB A-Mini B the best in its class.

JACK TO PHONO

Connecting your mobile device/tablet to your audio system has never been easier with our 2 step 3.5mm jack for a simpler connection.

HDMI

Using our in house HDMI testing facility, QED have designed premium HDMI cables to suit any budget. From our flexible and slimline profile to our exceptional Reference HDMI with its BandPass filter technology to reduce Jitter to Ultra low levels

OPTICAL

For all of your Optical needs, QED has an optical cable for you. For the more advanced, high bandwidth signals, Reference Optical Quartz uses glass technology to accurately send the information from source to receiver.

ETHERNET

The most common type of cable used for connecting products on a wired network. This cable connects wired devices together to the local network for file sharing and Internet access.

SUBWOOFER CABLE

Using technologies from our analogue cables such as complimentary conductor technology, your subwoofer will always perform to its best capability.

What is Airloc™?

Airloc™ is a form of cold weld system that permanently attaches QED Forté™ banana plugs to our entire range of speaker cables. One of the main reasons for choosing a QED speaker cable is the superior d.c. resistance characteristics offered by our exclusive use of 99.999% oxygen free copper conductors. It seems a shame then to ruin all this attention to detail by neglecting the most vulnerable area of the speaker cable chain - that of the physical interface between cable and amplifier or speaker terminals.

Seen under a microscope the surface of a typical copper strand is very rough and so using normal screw type terminals - such as found on binding posts or cheap banana plugs - electrical contact is only made in a relatively small number of places. Add to this a layer of oxidation - which is inevitable if copper is exposed to the air for even a short time - and the combined resistance of the cable and its termination can creep back up to levels present in a more inferior cable.

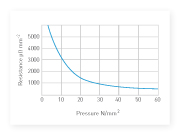

By using a cold weld crimp type termination Airloc plugs squash the conductors and plug together to improve contact area and reduce resistance. As can be seen in the graph, by the time the full pressure has been applied the resistance of the joint has reached a minimum value.

Now, because all the air has been removed from the joint there will be no oxidisation of the contact surfaces either so the low resistance will remain for the lifetime of the cable. During the cold weld process the cable and plug become one solid piece of metal. Since the copper contact has been effectively removed from the resistance equation we can concentrate on the plug to terminal resistance.

Now, because all the air has been removed from the joint there will be no oxidisation of the contact surfaces either so the low resistance will remain for the lifetime of the cable. During the cold weld process the cable and plug become one solid piece of metal. Since the copper contact has been effectively removed from the resistance equation we can concentrate on the plug to terminal resistance.

What are Forté™ Plugs?

The plugs themselves are made of solid brass which has roughly twice the resistivity of copper. For this reason our 4mm banana plug was devised so that its crosssectional area would be at least double that of the cable to which it was connected effectively cancelling out the extra resistance of the plug material. QED then plates the connector with high purity gold which has a resistivity almost as low as copper but more importantly does not oxidise in air. The relatively smooth gold surfaces provide a larger contact area than the uneven copper strands in the cable and because the gold will never oxidise the contact surface remains clean and low resistance for life.

The new Forté plug pin section is designed to maximise contact area throughout the wide tolerance range encountered in 4mm amplifier and speaker sockets. Here some are quite tight whereas others are loose, so the spring loaded Forte blade is designed to fit into smaller and larger sockets with equal insertion force. This means that the contact area is maximised and the connection remains uniformly tight.

QED Forté with Airloc technology; guaranteed low resistance and strength - for life.